Bridging physics, simulations, and AI to deliver faster, explainable insights in manufacturing operations

Physics-Based Digital Twins

AI for Manufacturing: Moving from Data Alone to Physics-Guided Intelligence

Digital twins have evolved beyond the early promise of real-time visibility and predictive maintenance. With increasing demand for faster process development and reduced reliance on physical trials, manufacturers are now expecting digital twins to simulate, predict, and optimize complex industrial processes more reliably and at greater speed.

The shift is being driven by a critical realization: purely data-driven approaches often fall short in industrial environments.

The Shortcomings of Data-Only Models

While the idea that “more data leads to better models” may work in consumer applications, manufacturing processes bring unique challenges:

- Data is sparse across the full range of operating conditions

- Failure cases are rare and poorly captured

- Inputs and KPIs are multidimensional, involving thermodynamics, flow, material properties, and equipment design

Predicting Process KPIs: From Months to Minutes

Physics-guided ML models, trained using simulation and experimental data, now enable manufacturers to predict critical global KPIs such as:

- Blend uniformity in Powder Blending

- Coating uniformity index in Tablet Coating

- Ribbon density or granule size distribution in Roller Compaction

- Tablet weight uniformity in Direct Compression

- Dissolved oxygen level or mixing time in Bioreactors

These predictions, which once required weeks of physical trials or lengthy simulations, can now be produced in minutes or even instantly once the surrogate models are trained.

Enter Physics-Informed Neural Networks (PINNs)

Unlike Data-only ML models, Physics-Informed Neural Networks (PINNs) incorporate the fundamental governing equations of physics directly into their learning process. This makes them ideal for generalizing beyond observed data, ensuring physical consistency, and delivering explainable predictions.

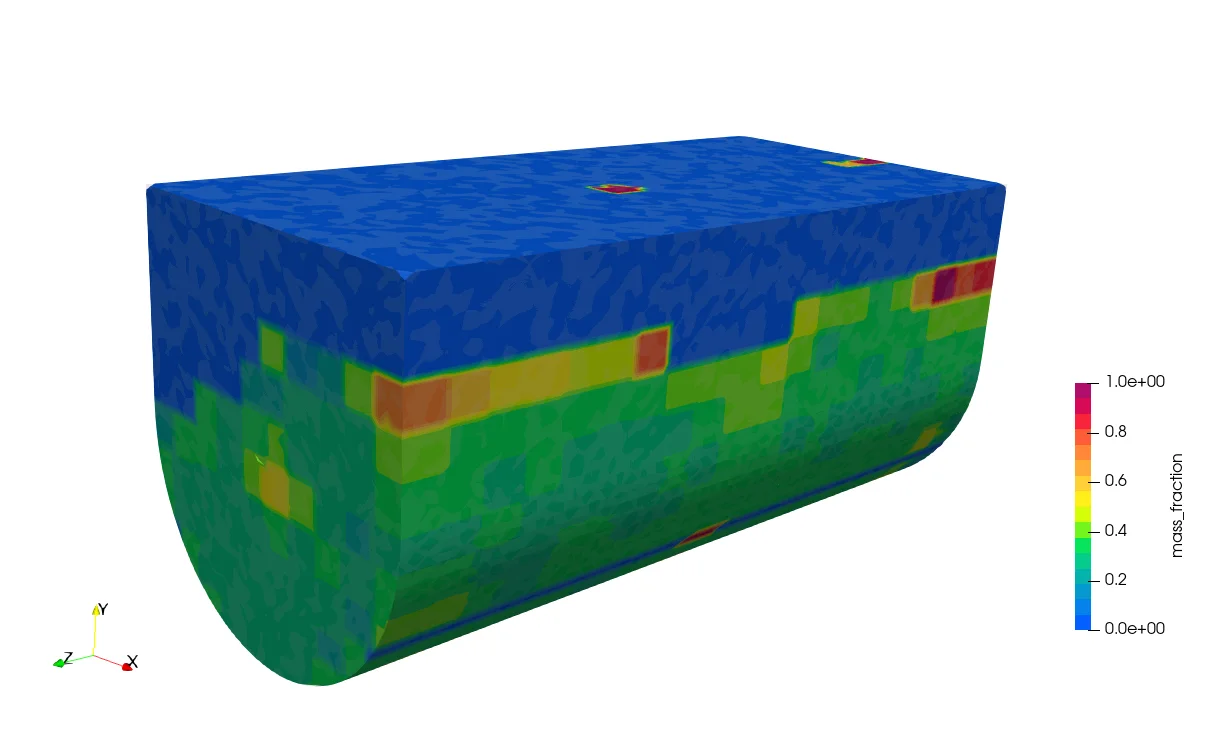

PINNs can be effectively used to provide localized KPIs and 3D field predictions,including:

- Mass fraction distribution within blenders

- Compaction pressure distribution across roller width

- Oxygen concentration gradients or shear zones in bioreactors

These insights help uncover non-uniformities and edge-case conditions that global KPIs may miss, enabling more precise control and better process understanding.

Example: Mass Fraction Prediction in the Blender

In case of powder blending applications, mass fraction variation across the blender is critical. The ML model trained using PINNs predicts the mass fractions across the blender.

Democratization

The ultimate goal is not just analysis, but deployment to users who are not necessarily expert in simulation or AI. They are interested in KPI predictions and drive process improvement. We package our trained models as AI-integrated Apps that hide the complexity of simulation setups, solver orchestration, and data handling.These apps are:

- Intuitive for non-experts to use

- Explainable for engineering teams to trust

- Fast enough for real-time decision-making

Whether it’s process development or production optimization, users can access insights without dealing with simulation infrastructure.

Stay tuned for more deep dives and case studies.

Why Intelimek

At Intelimek, we empower companies in pharma, food, automotive, and specialty materials to build physics-based digital twins that accelerate development and improve operational consistency. Our work combines physics simulations (CFD, DEM, FEM), machine learning, and domain expertise into smart, scalable solutions.

Want to explore how this applies to your process?

Contact us to learn more or see examples in action.