A Journey from Shortcuts to Real Design

When Jenike Meets AI

Stage 1 — The ask to Open AI (ChatGPT)

It started simply: 'Can you run Jenike hopper angle and arching dimension calculations with my test data?' I had three clean Excel files of a sample material: flow function data (σ₁ vs σc from shear tests), wall friction data (Φ’ vs normal stress), and bulk density data (ρb vs stress). The goal: calculate outlet sizes and hopper angles for a lab-scale bin with an effective head H = 0.25m.

Stage 2 — First-Pass Numbers

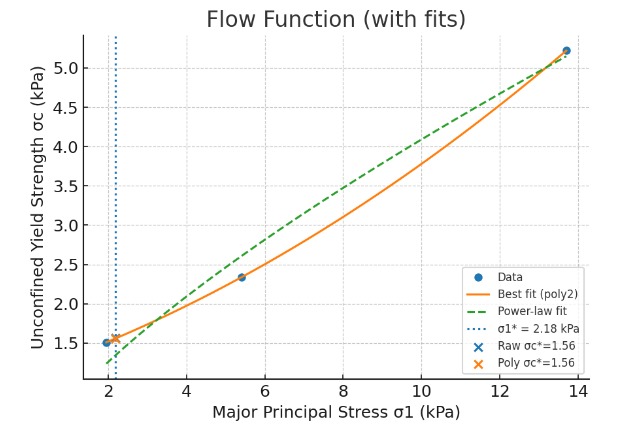

Using the data, and asking ChatGPT to perform some curve fits, the AI found the following:

- Bulk density at design stress: ≈ 896 kg/m³

- Design consolidation stress σ₁*: ≈ 2.20 kPa

- Unconfined yield strength σc*: ≈ 1.57 kPa (raw) or 1.56 kPa (polynomial fit)

- Flow function ff: ≈ 1.4, cohesive powder (Note, this is actually the flow function coefficient,

- which is the consolidation stress divided by the unconfined yield strength; ff is the flow factor, which is the ratio of the arch supporting stress to the consolidation stress.)

- Mass-flow half-angle: ≈ 37.5°

From this, ChatGPT produced the following minimum outlet dimensions:

- Circular outlet diameter: ≈ 0.89 m

- Slot outlet width: ≈ 0.45 m

Stage 3 — Tools and Outputs

The AI packaged the results into:

- Plots of flow function, wall friction, and bulk density

- An Excel calculator with Jenike-style equations

- A draft PDF report with summary numbers

At this stage, everything looked neat, but something didn’t feel right as I know from experience the devil is in the details.

Stage 4 — The Consultant Check

A big thanks to Greg @Greg’s LinkedIn for sharing his detailed Excel approach, which helped validate the calculations. We’ve now implemented the same rigor inside the Intelimek platform, with a much cleaner, user-friendly interface. The numbers with this validated approach did not match the AI calculations.

The reason: the AI had used a simplified shortcut approach instead of Jenike’s chart-based method.

Details of the Default Factor Method

By default, ChatGPT used what can be called a 'factor method' for arching dimensions:

- Dmin = C_circ × (σc / (ρ g))

- Wmin = C_slot × (σc / (ρ g))

where Dmin is the minimum circular outlet diameter, Wmin is the slot width, σc is the unconfined yield strength, ρ is the bulk density at the design stress, and g is gravity.

The constants C_circ and C_slot were assumed as typical engineering shortcuts:

- C_circ ≈ 5 (range 4–6)

- C_slot ≈ 2.5 (range 2–3)

These constants are not from Jenike’s original work, but approximations that some practitioners use for quick scoping. Jenike’s analyses give constants (H(θ′)) approximately equal to 2 for hoppers with round outlets and 1 for hoppers with slotted outlets.

Stage 5 — Lessons Learned

Key lessons:

- AI gives you a number, but not necessarily the right one. By default, it used shortcut constants.

- Curve fitting matters: using a power-law fit underestimates σc* and leads to undersized outlets (~15% smaller). In addition, curve fits to the friction angles and wall friction data can be complicated for various types of material, especially ones that are cohesive.

- Jenike’s actual method uses charts for flow factor (ff) and H(θ′), not constants.

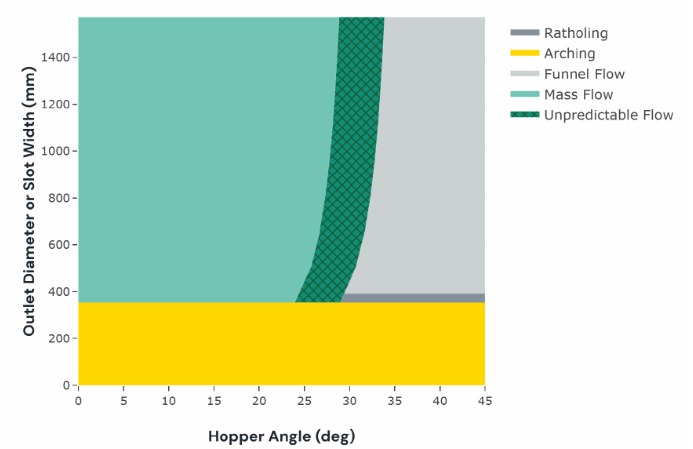

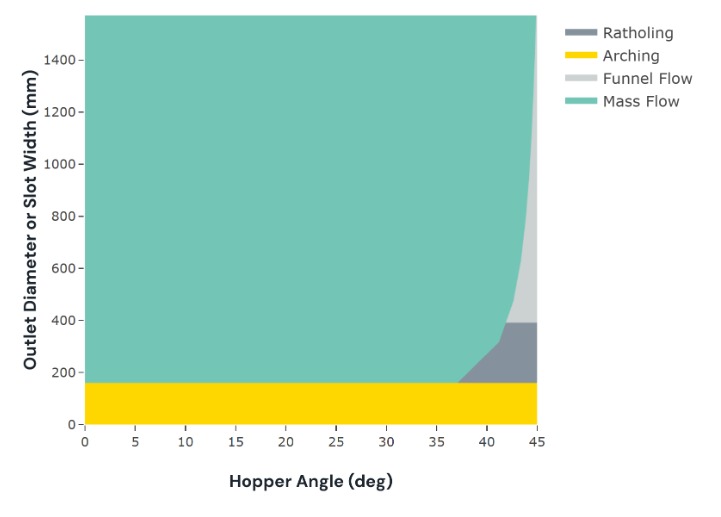

The Intelimek application takes into consideration many such details and gives the user practical guidance on flow regimes in the hopper for an effective head of 0.25 m (as shown below) for both conical and planar geometries.

Another important lesson is that AI can introduce misleading results. Even small deviations of 10 to 15 percent in outlet size predictions can translate into significant operational risks in practice. Intelimek’s platform addresses this by implementing the complete Jenike methodology rather than relying on shortcuts.

Key solution features include:

- Structured materials database – captures flow function, wall friction, and bulk density data directly from tests, ensuring consistency and traceability.

- Simple study setup – users can quickly configure analyses by selecting the powder and wall material from the database.

- Automated regime maps – visualize mass flow, funnel flow, arching, and ratholing across hopper angles and outlet dimensions, while accounting for head height and geometry type.

- Direct hopper risk assessment – evaluate real equipment by entering actual hopper dimensions for an instant pass/fail assessment.

- Session management – calculations are preserved for future reference, with options for structured report downloads.

- Flexible deployment – available on-premise or in the cloud, with user-specific data management for secure collaboration.

- Customizable for customer needs – the platform can be extended to integrate directly with client workflows. Examples include linking hopper results with CAD models, embedding flow profile visualizations, or incorporating discharge rate equations to reflect plant-specific constraints

This provides a reliable and professional alternative to traditional spreadsheet-based approaches.

Final Thought

AI is a powerful calculator. It can interpolate, fit curves, and generate slick models. But in

bulk solids handling, domain knowledge is the difference between a working bin and costly downtime. If you want quick scoping, AI can help. For accurate predictions for defensible designs or material flow, the Jenike charts and expertise must be applied. Our platforms integrate such expertise in an easy-to-use, customizable way for saving multi-million dollar flow problems.